What Does It Mean To Railroad Fabric For Window Treatment Design?

Fabric comes in rolls, common sense. Have you ever thought about how it is cut as it comes off that roll? Which direction is it supposed to go? Does that depend on what you are making or how you are making it? Yes, Yes & Yes are the answers.

Most people understand the concept of ‘Up the Roll’ (UTR) and ‘Railroading’ (RR), but it can still be difficult to explain. The implications of choosing to railroad a fabric vs. run it UTR are tremendous and should not be passed over simply because of some difficulty in understanding the concept.

That is why we relish the opportunity to spell out this concept in words and with pictures. We have also included an example at the end that will hopefully highlight just how vital this decision is when it comes to the amount of fabric you need for a certain job and ultimately how much money you are spending.

So without further ado…

What is railroading?

Railroading refers to a specific direction fabric is used as it comes off the roll.

Fabric being used Up the Roll (UTR) means that it is ‘looked at’ and used literally up and down the roll of fabric just the way that it comes off the roll (see figure 1). What you see as it is spooled off is what you are going to get in application on the window. If a treatment is wider than the roll then multiple pieces are going to be cut and serged together side by side.

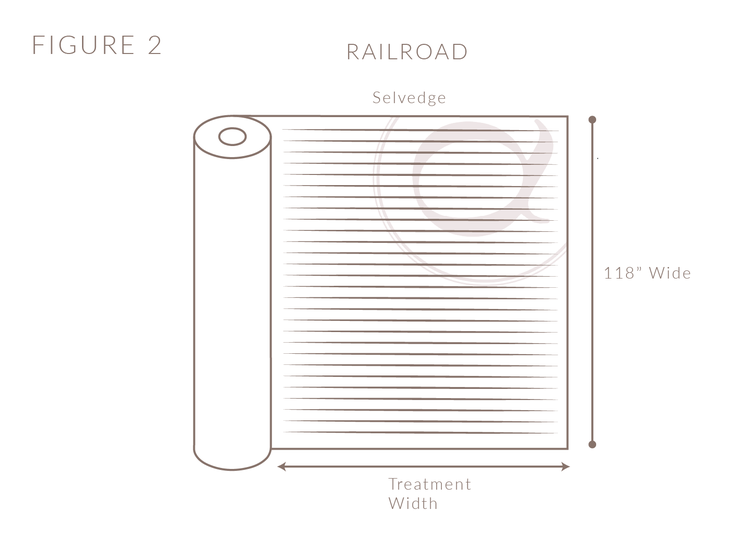

Fabric being Railroaded means the fabric width becomes the length and as you see the fabric from the side with selvedge at the bottom and selvedge at the top is what you are going to see with the finished product (see figure 2).

Why Would I Railroad?

Railroading fabric is a decision that may be made for namely two different reasons. One, to run a pattern in a specific way. For example if a fabric is chosen that has vertical stripes running up the roll but design wants those stripes to run horizontally, then we would need to railroad the fabric.

Second, railroading may be chosen in order to save on fabric. Railroading a fabric means that we are able to cut the exact amount of fabric needed, minimizing waste. Let's say we are making a treatment 150" wide by 105" long...

If we have to run the fabric UTR and it’s only a 110” good, then we have to make 2 different cuts of the specified length (one of those a half) and serge those pieces together in order to create a piece with a width of 150” (see figure 3).

If we are railroading the fabric then we simply turn it on it's side, measure out 150" and cut it to its finished width (see figure 4).

The Caveat

If you are railroading the fabric then the length cut size is limited by the width of the fabric. Therefore the width of the fabric becomes the limitation on the finish length that can be made. For example if you have a treatment that needs to be 115” long but your fabric is only 110” wide, then it cannot be railroaded. This is not always clear cut as deductions must be made to account for top and bottom hems. If you ever have a fabric and finish length that you would like us to check on if it can be railroaded, please let your sales manager know.

How Much Fabric Will It Really Save Me?

Here we will solve for an example problem to show you exactly how much can be saved when fabric is railroaded. In this example we will be treating 100 windows with treatments finished to a rod width of 75” and a finish length of 100” @ 200% fullness, with a sheer fabric which is 118” wide.

The fabric yield per treatment UTR will be 6.77 yards.

The fabric yield per treatment Railroaded will be 4.9 yards.

That means that over the span of the entire job, you would need less yards of fabric if you used it railroaded rather than UTR, and that my friends equates to a lot of dollar bills.

Keep In Mind…

Sometimes you cannot get around running a fabric UTR. Either it’s patterned and you need it to run that direction for pattern sake, or maybe you have a very tall treatment that must run UTR.

Photo Credit to: Kevin Sullivan

We hope this has proved beneficial to you as you consider the direction a fabric needs to be ran for a specific job!

See More Fabric Resources