How Much Fabric Will I Need For My Drapes?

Understanding Fabric Yield

We understand in the life of a designer an important part of the job is a cost analysis. In designing a hotel room or an entire property you need to be able to estimate how much each piece is going to cost and subsequently, how much fabric you are going to need for drapery. This is a more complex question than you may think, as there are multiple factors that go into the production of single drapery panel. Therefore, estimating the fabric is not necessarily as straight forward as we may like, yet armed with a bit of information and a list of formulas, it is definitely doable!

It should be noted that this is not meant to be a substitute for an official estimate (usually included with a bid) from a drapery manufacturer. As different manufacturers take different allowances for factors such as hems, waste, overlaps, etc. In these situations, we will give you a conservative number to use when factoring, but depending on the drapery manufacturer that number could be less or more than what each manufacturer uses in their estimating.

We will work through two different scenarios; the first, using fabric UTR (up the roll), and the second RR (Railroading) fabric.

For Supporting Information…

If you have not read our blog, ‘What Does It Mean To Railroad Fabric?’ we recommend that you do, for an introduction to these concepts.

Fabric Yield Using Fabric UTR

The first thing that you will need to do is gather all of the raw data. You need consider all of the variables at play, which are Rod Width, Finish Length, Fullness & Pleat Style. Once you know all of these factors you can begin to work thru the formulas below.

We start by figuring the flat finished width of a treatment. As we discussed in our previous post, ‘What is Fullness?’, a treatment starts as a flat panel and as fabric is used in ‘pleats’ or the undulating waves of ripplefold it gains its fullness.

Let’s Begin With Rod Width

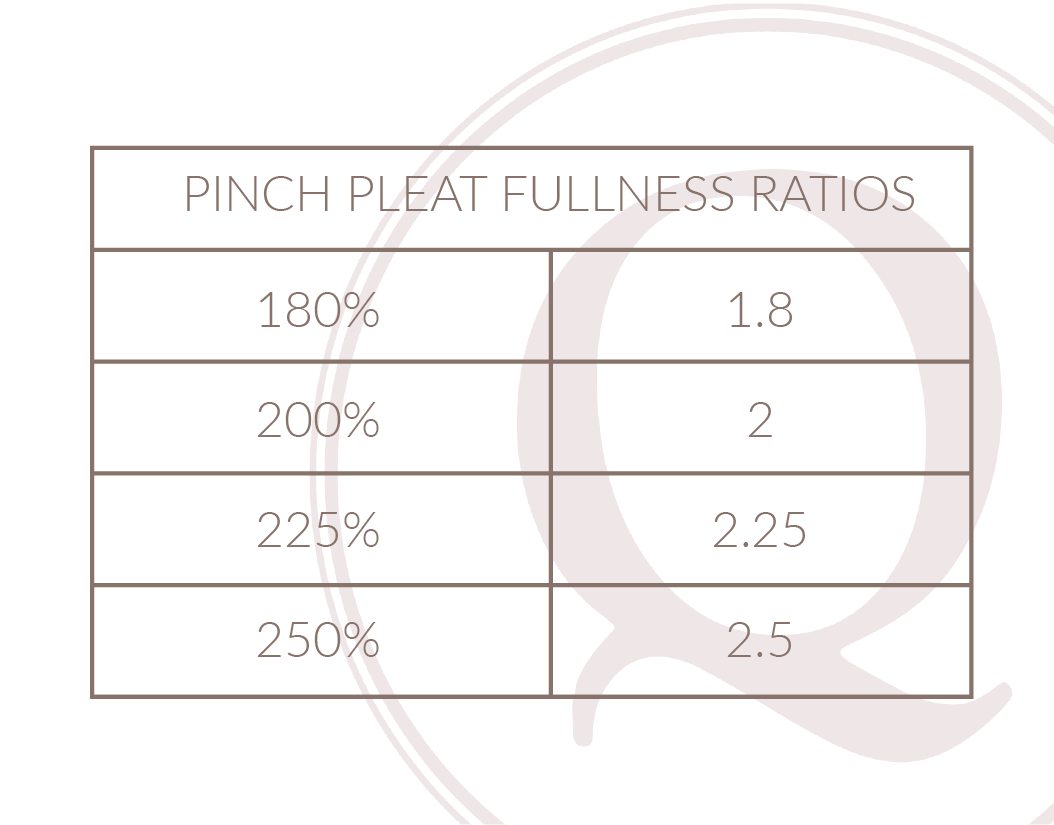

Rod Width tells us how wide you want the finished treatment to span. We multiply that number by your Fullness Ratio. Note: the fullness ratio is based upon your pleat style as well; whether pinch pleat or ripplefold (please see the chart below showing all fullness ratios).

You will add to this total an allowance for hems, returns & overlaps (this is a factor that changes per manufacturer and based upon a number of extra factors), we suggest for a rough estimate that you use 25” as a conservative amount.

Next, take that Flat Finished Measurement and divide it by the width of the fabric you are using (usually either 54” or 118”), this will give you the # of fabric widths needed to produce your drapery treatment. This number should be rounded up to the next whole width.

Now, Finish Length

It’s fairly simple. You take your Finished length and you add to it an allowance for Hems & Headers (we suggest using a conservative 16”). This gives you the fabric cut length.

Now you are finally ready to figure the total number of yards to make the final treatment. Take the # of widths (rounded up to the next whole width) and multiply that by your Cut Length. Your answer will be the total amount of fabric in inches needed.

Take that number and divide by 36” (the number of inches in a yard) and you will have figured the number of yards needed for a panel.

The final step is to multiply that amount by .05 and add it back in to figure out your total with waste from cutting included. Round that number up to the nearest quarter yard and you have figured your total yardage!

Figuring Fabric Yield Using Fabric Railroaded

Before we begin walking you through formulas, we need to first explain when it’s better to use fabric Railroaded. In the above explanation we noted that 16” should be added to the Finish Length to figure Cut Length. This allowance is very important when using fabric railroaded as well, because you can only use a fabric railroaded when its finish length is less than the fabric width minus those 16”.

Following that logic if you have 118” wide fabric, the longest finished length possible is 102”. If that is possible and you choose to railroad fabric here are the steps you must take…

Let’s Start With Rod Width… Once Again

First, take your Rod Width and multiply by your Fullness ratio, then add your returns & overlap allowances (we recommend 25”) to figure your Flat Finished Measurement. Your Flat Finished Measurement at this point is also your Fabric Yield in inches.

Divide that number by 36” (number of inches in a yard), which will give you the Fabric Yield in Yards.

Take that number and add in waste by multiplying by .05 and adding it back to the Fabric Yield in Yards and you have the Amount of Fabric needed, which you will simply need to round up to the nearest quarter yard.

We hope you have at least a basic understanding of how to equate fabric yield as well as practical tools to do this on your own. Using these formulas can be an extremely handy tool in the hotel designed, budgeting, and managing processes.

We hope this was helpful. Don’t hesitate to ask us if you have any questions!

Check Out Related Resources