Understanding Drapery Hems & Weights

The purpose of this post is to highlight some common understandings and design aspects that may guide you in your decision process.

Hems & Weights may not be seen as very big deal in the spec writing process for window treatments but it is an important detail to consider. We’ve created a resource card that explains how each of these are made, so in this place we will not be rehashing that same information. Download it here and keep it at your desk for easy access.

It should be noted that all drapery treatments need a bottom hem, side hems & a top hem. The top hem is almost always dependent upon the Pleat Style that is chosen. The side hem is typically a 1 ½” Double.

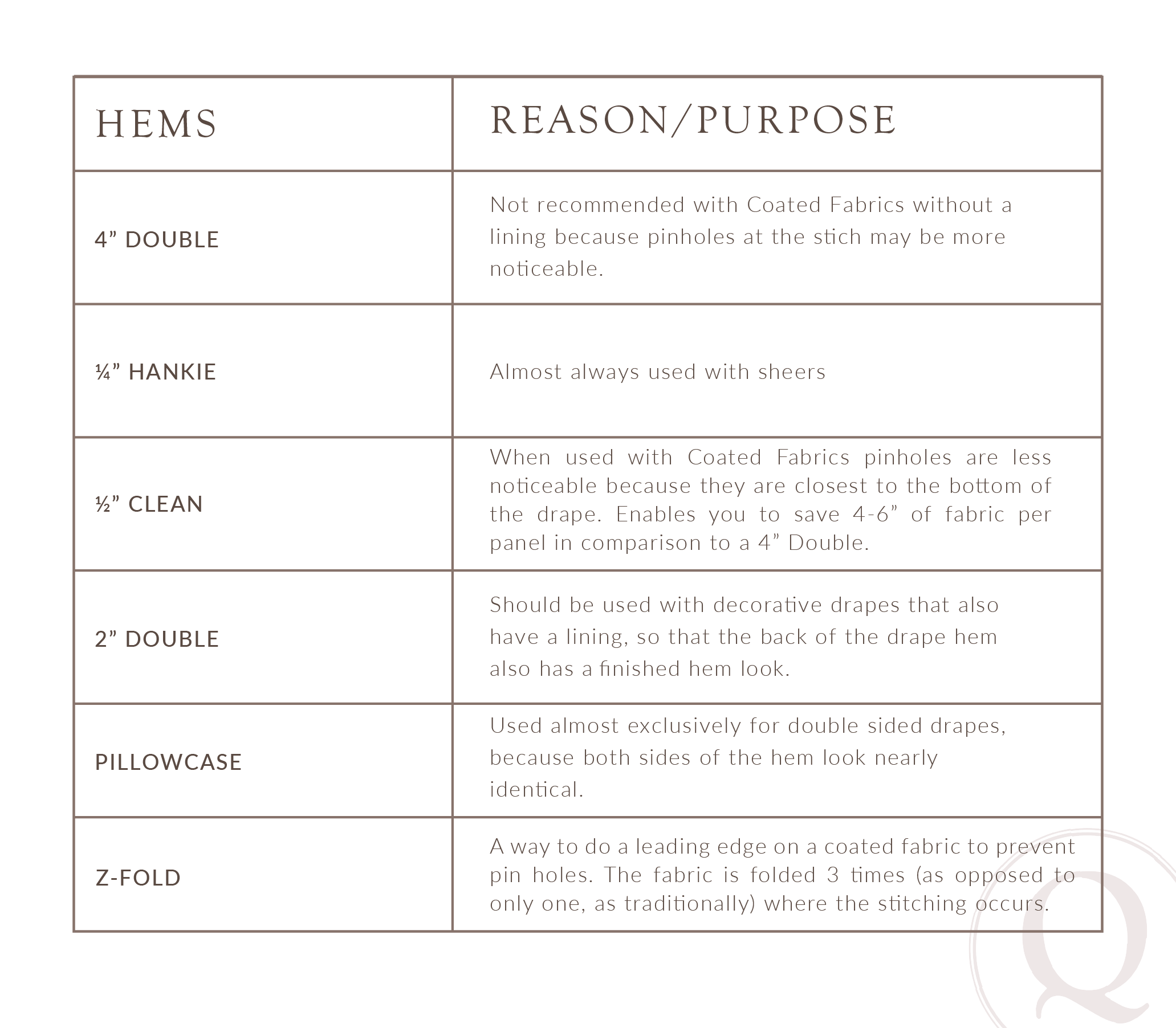

When this is not specifically noted in specs, it can become a problem for our team! The bottom hem, as small and nuanced, as you believe it may be, draws attention of the eye and therefore, is extremely important in finishing a drape. There are 4 typical types and 3 of them create very distinct looks; they are the 4” double, ¼” hankie, ½” clean & 2” double.

There are some generalizations for each of the hems listed above that we want to offer as guidance in your spec writing, so that you have a basic understanding of when to use each type!

Types of Weights

Types of Hems

Z-FOLD SIDE HEM

Illustration

Remember to download the resource card as well to have a quick cheat sheet of all the hems & weights that are available!

Check Out Related Resources